Formic acid atmosphere heating refers to

Fluxless soldering is currently gathering attention for its environmental impact and shortened process. In the case of reflow soldering, it is generally necessary to clean with a solvent after reflowing as flux is applied. As for fluxless soldering, since flux is not applied, the oxide film is removed by the reduction effect of gas and high wettability can be ensured. Furthermore, it is possible to improve the quality and strength of soldering by performing evacuation control. Regarding the formic acid atmosphere heating with the SMT Scope, “improvement of wettability by the reducing effect of formic acid” and “reduction of voids by vacuum”can be verified.

1. Reduction effect of formic acid -observation with SMT Scope-

The oxide film on the metal surface can be strongly removed and high wettability can be ensured even under the condition of fluxless due to the reduction effect of formic acid. The reduction effect of formic acid can be confirmed from the recorded observation video.

In addition to controlling the temperature, the introduction and stop timing of vaporized formic acid into the chamber of SMT Scope and formic acid concentration can be set freely.

2. Void reduction effect

Sufficient wettability can be ensured even under the condition of fluxless in a formic acid atmosphere and the suppression of voids by vacuum can be confirmed.

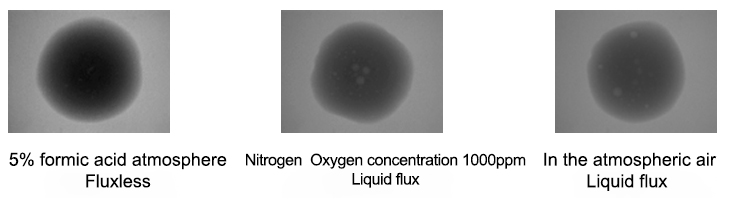

Comparison of transparent photos by X-ray

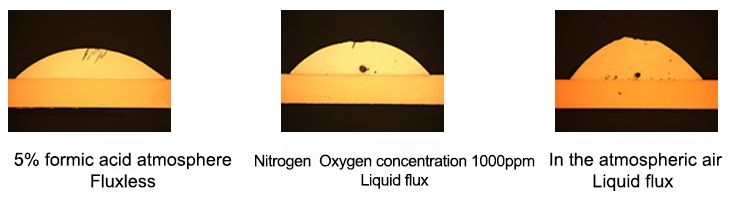

Comparison of sectional images by OM

The timing of vacuum deaeration can be set freely on the profile. It is possible to remove air bubbles inside the solder due to the vacuum effect and further suppress the voids.

3. Effects on the Environment

In the case of fluxless soldering, the cleaning process after reflowing will not be needed and environmental burden will be reduced . In addition, the reduction temperature of formic acid is as low as 150℃ compared to 270℃ of hydrogen, which will ensure the wettability to be stable even at the condition of low temperature reflow. Highly reliable soldering is possible by eliminating the causes such as metal corrosion and migration due to flux residue. The performance, reliability and life of the product can be improved through void free implementation realized by vacuum.