SMT Scope supports JIS test of solder paste. Please contact us for the evaluation methods.

Displacement detecting wettability test

Wettability test of solder paste JIS Z 3284-4 4.5

Overview

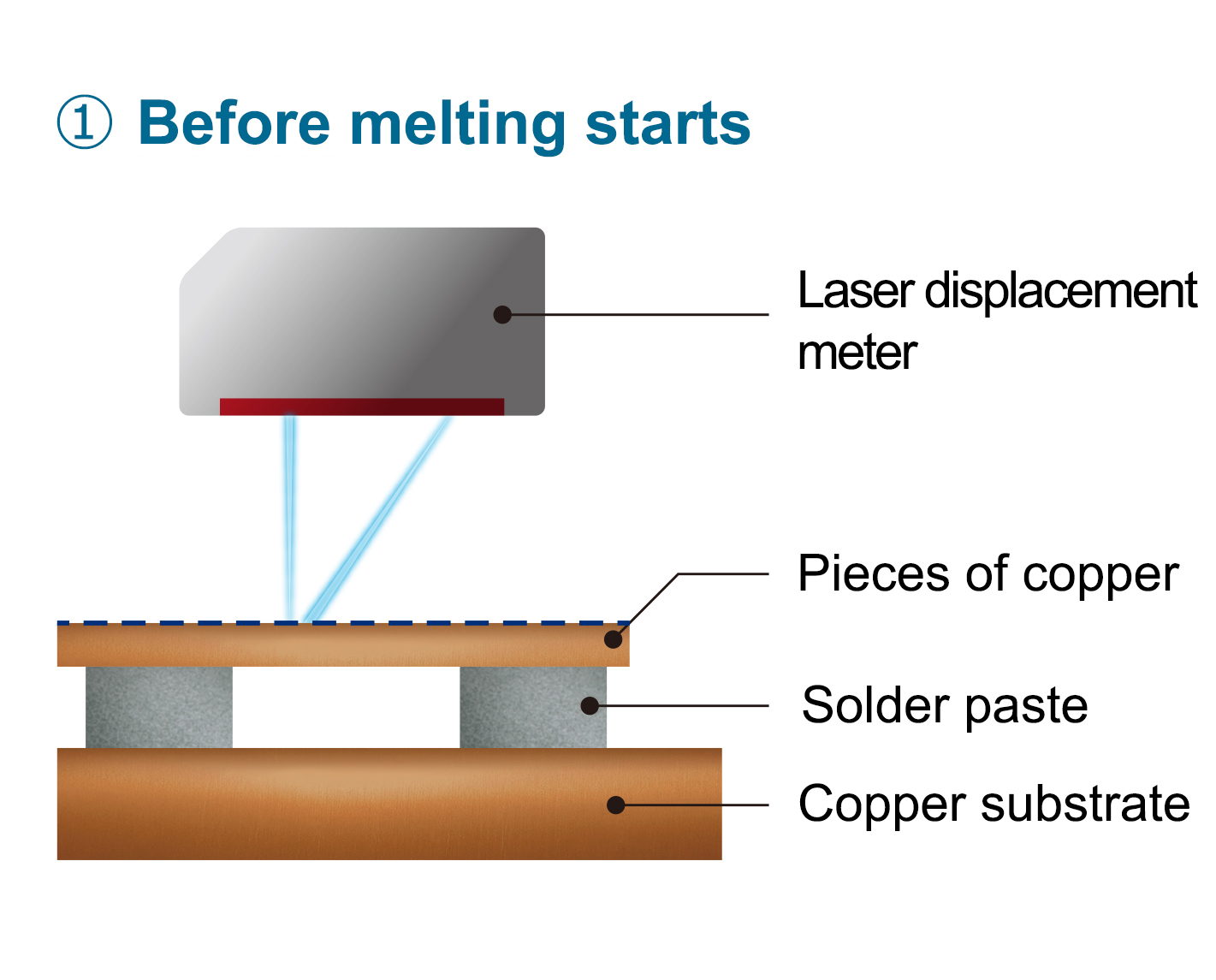

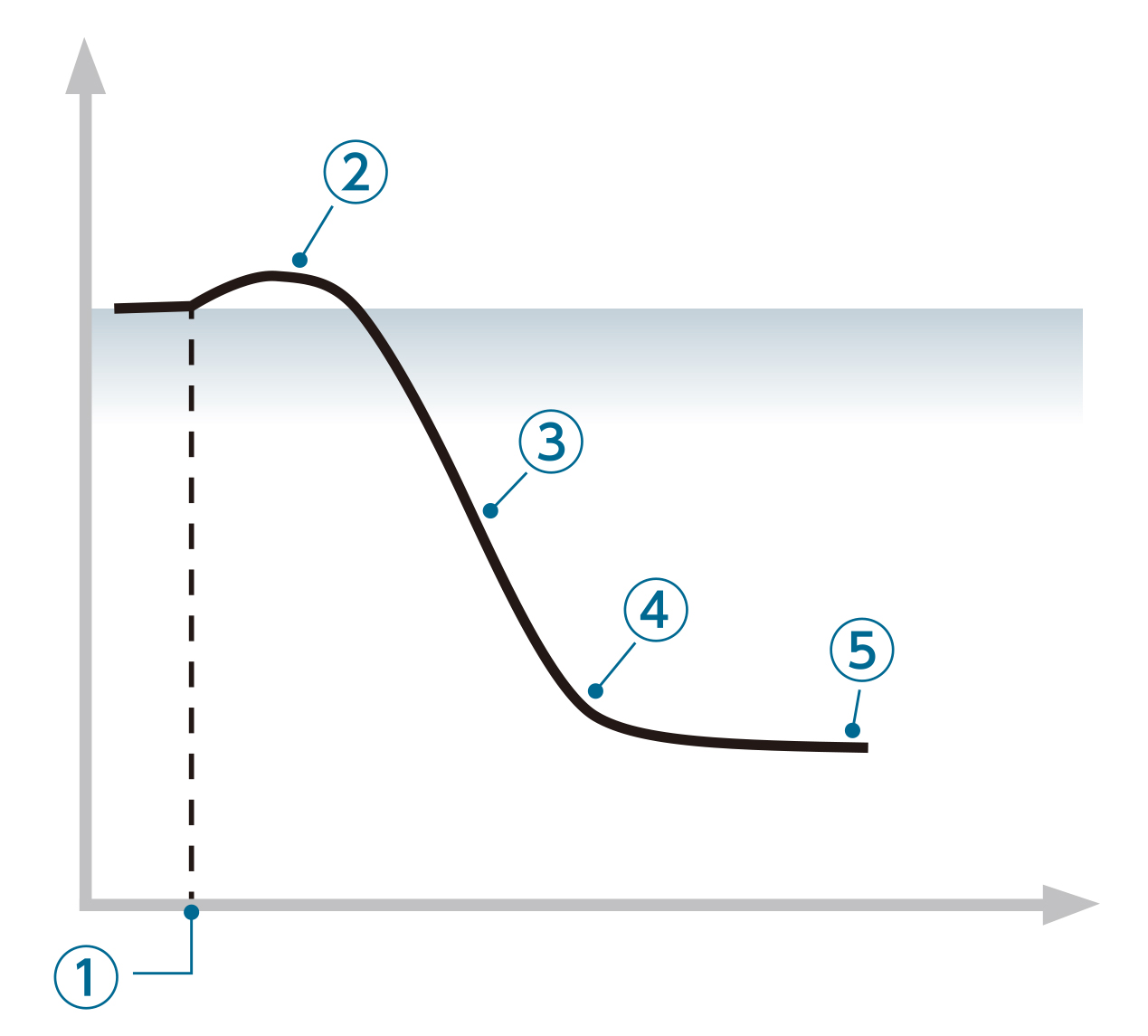

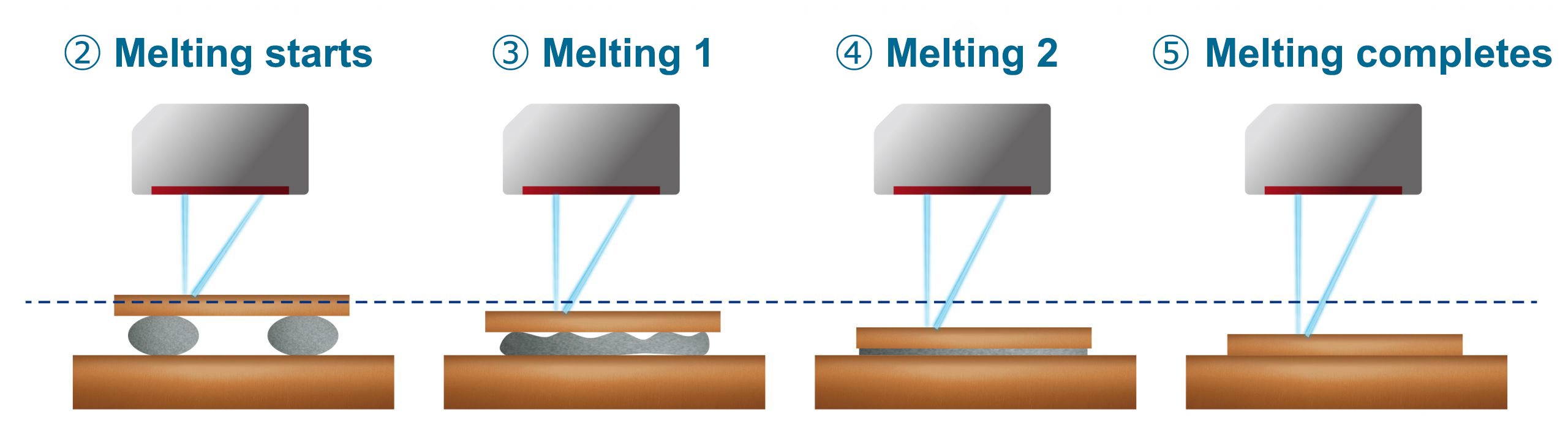

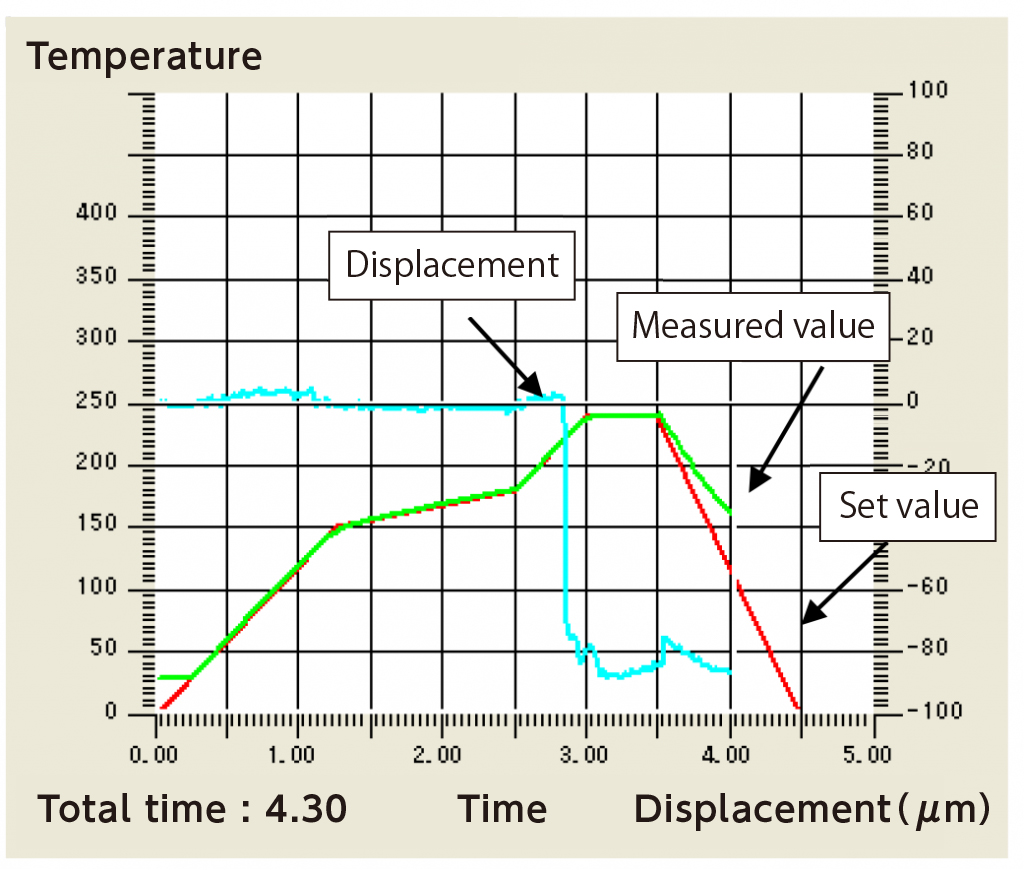

The wettability of solder paste can be quantitatively evaluated by measuring the phenomenon of displacement in the vertical direction of the standard test piece when the solder paste melts with a non-contact laser displacement meter.

Evaluation principle

Evaluation method

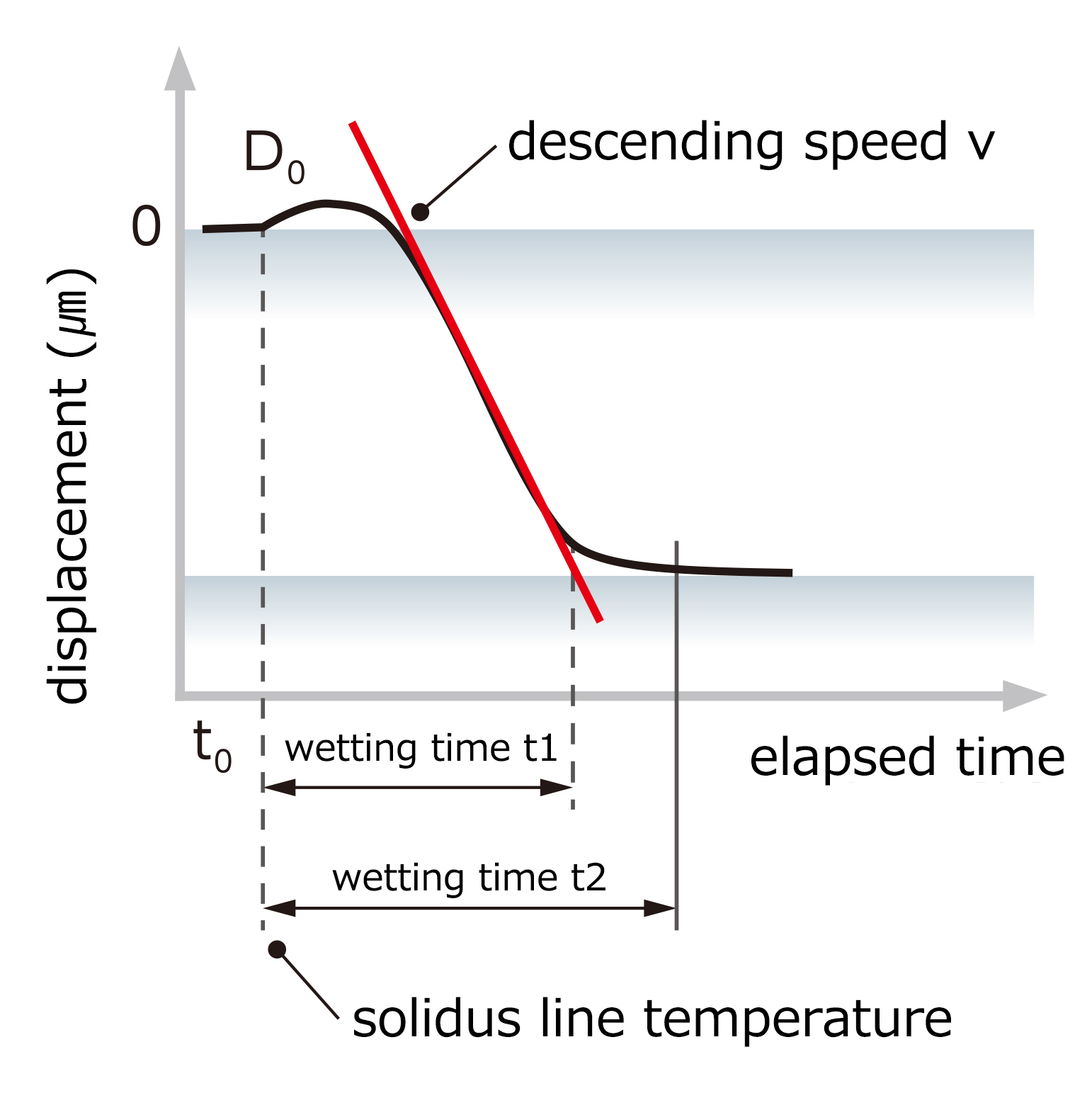

It is evaluated by the “descending speed ν” and the time from the solidus line temperature “wetting time t2” and “wetting time t1”.

Features

- The standard test pieces can be preparated just by one original jig.

- Tests can be performed repeatedly under the same conditions due to heating control with good followability and reproducibility.

- Temperature profiles can be freely set based on the reflow conditions.

- High-sensitivity wettability test can be performed by non-contact laser displacement measurement.

Measurement example

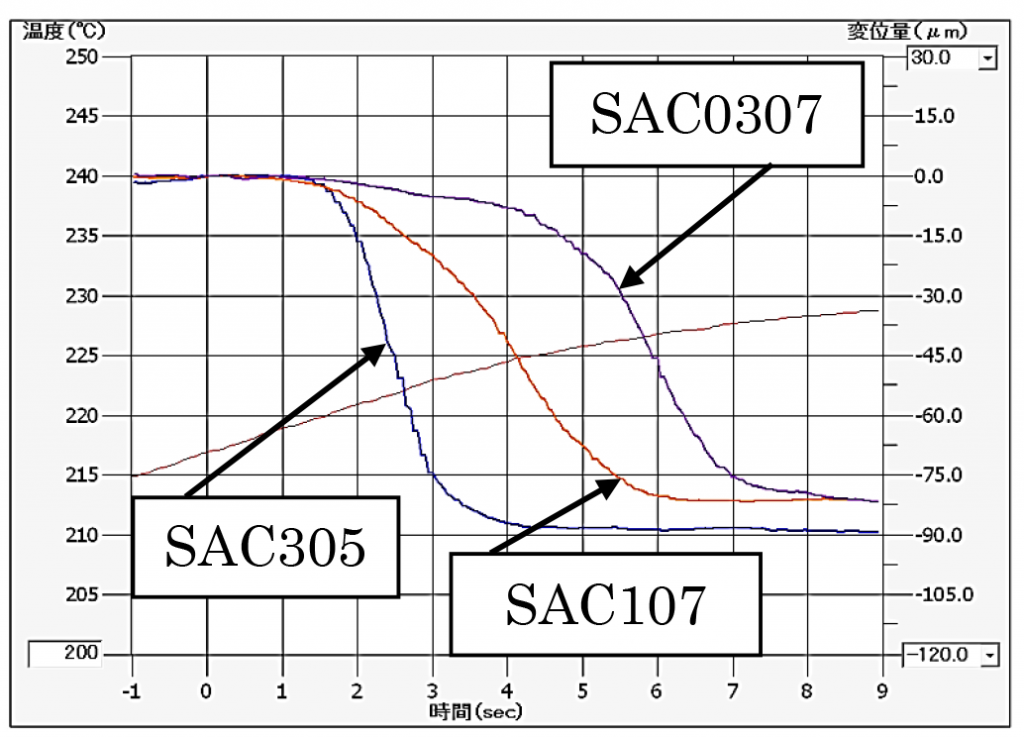

Comparison results due to the differences in the metal composition of solder paste

| Metal composition | Wetting time t1(sec) |

Wetting time t2(sec) |

Descending speed ν (μm/sec) |

|---|---|---|---|

| SAC305 | 3.21 | 4.40 | 77 |

| SAC107 | 5.51 | 6.60 | 27 |

| SAC0307 | 6.99 | 9.15 | 37 |

As it is clearly indicated in this table, the solidus temperature is all the same(217℃), but the liquidus temperature will rise when the content of Ag decreases.

High temperature observation test JIS Z 3285 5.5

Characteristic test methods of solder paste for micro-joining

Overview

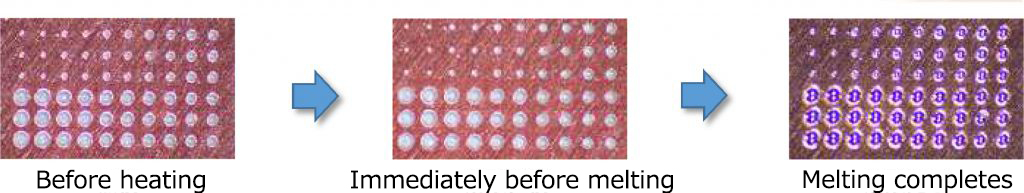

It was established in December 2017 as a new wetting characteristic test methods of solder paste for micro-joining. With type7 and 8 targeted to be the particle size of solder paste, the drooling behavior and state of reflowability from printing to preheating of reflow process will be evaluated.

Evaluation method

The video taken during heating is evaluated by an evaluation index of reflowability.

【Sagging phenomenon】

Print diameter with the minimum interval where no bridges occur will be evaluated at the end of the preheating time.

【Reflowability】

Evaluated by the evaluation index of reflowability indicated in the standard documentation.

(If there are multiple evaluation indexes for each print diameter, all the evaluation indexes should be recorded)

【Melting characteristics】

All 6 locations with the same print diameter are evaluated at the temperature at which they are melted under a certain state by applying the evaluation index of reflowability indicated in the standard documentation.

Features

- The standard test pieces can be preparated by our original metal mask.

- Tests can be performed repeatedly under the same conditions due to heating control with good followability and reproducibility.

- Temperature profiles can be freely set based on the reflow conditions.