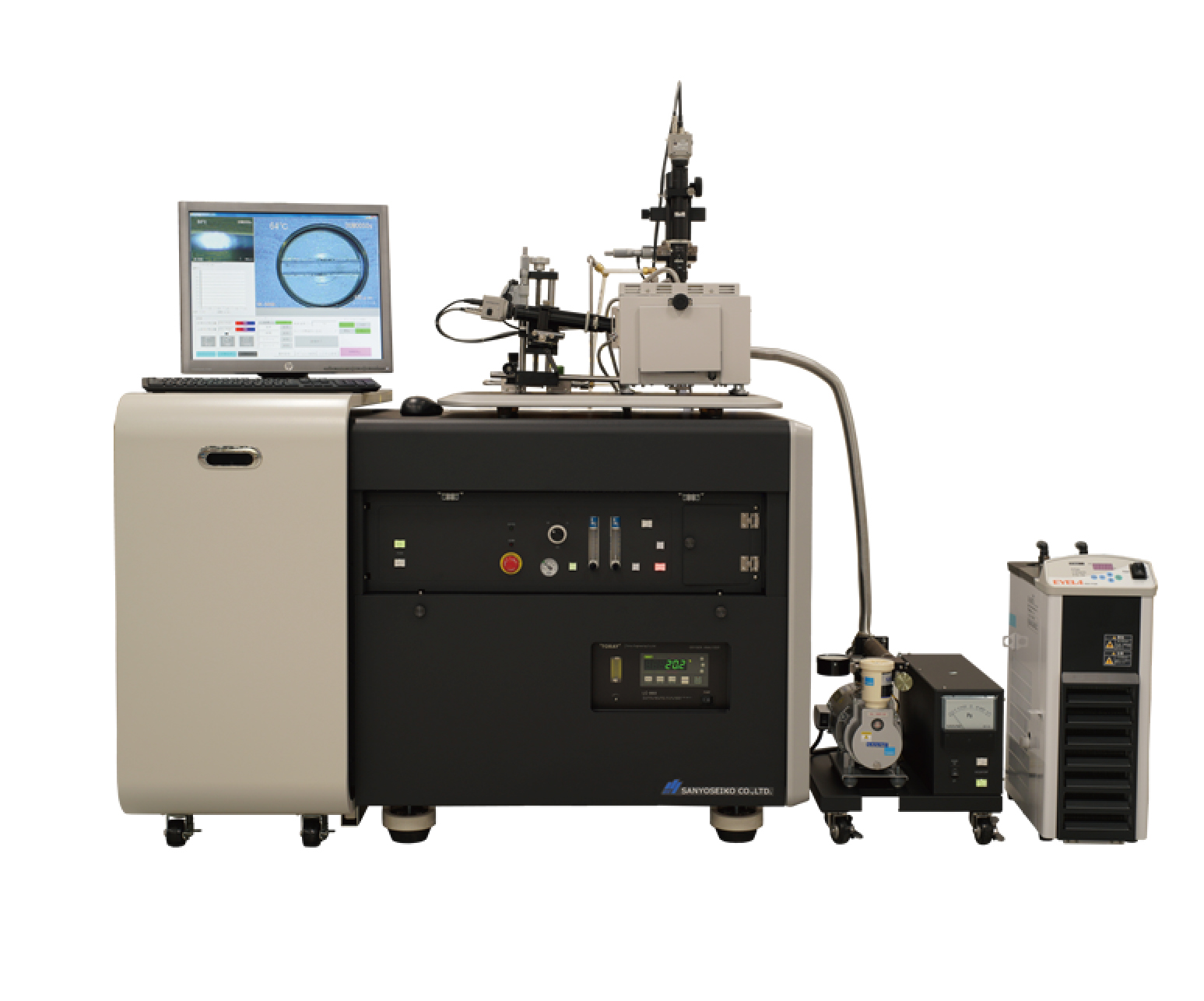

High temperature observation equipment “SMT Scope”

The high temperature observation SMT Scope provides real-time observation of materials as they change under high temperatures, from room temperature up to 900℃.

1. Precise and repeatable temperature control

A selection of models are available to meet your specific requirements. We also provide sample evaluation tests.

SK-5000 (Up to 400 degrees)

For evaluation and analysis of narrow pitch bonding of solder and ultra-small components(0402)

SK-8000 (Up to 800 Degrees)

For evaluation and analysis of sintering, brazing filler metal and plating materials of glass paste

2. Various heating atmospheres

In addition to atmospheric and nitrogen atmosphere heating, it is possible to control the oxygen concentration in a nitrogen atmosphere. Besides the handling of formic acid, hydrogen, forming gas and high vacuum, dew point and oxygen concentration adjustment is available as well. Please feel free to contact us for details.

Vacuuming under the condition of nitrogen heating

Learn more about various heating atmospheres

3. High-magnification observation without fluctuation

It can be varied from 0.078 to 20.0 times optically, and even fine powders of solder paste can be observed. Sample fumes and organic substance which has become gas will be eliminated by flowing the atmospheric gas in the chamber and degradation of image quality due to the fluctuations can be prevented, which will lead to high-quality images.

4. Equipped with image analysis and video editing capability

The recorded video can be edited speedily by editing software. The length, angle and area of the still images cut out from the playback screen can be measured by the measurement software.

5. Wettability test of JIS standard

It supports JIS Z 3284-4 4.5 displacement detecting wettability test, which is a wettability evaluation method for solder paste. It conforms to JIS Z 3285 5.5 high temperature observation test, which is a characteristic test method of solder paste for fine bonding.